Process engineering

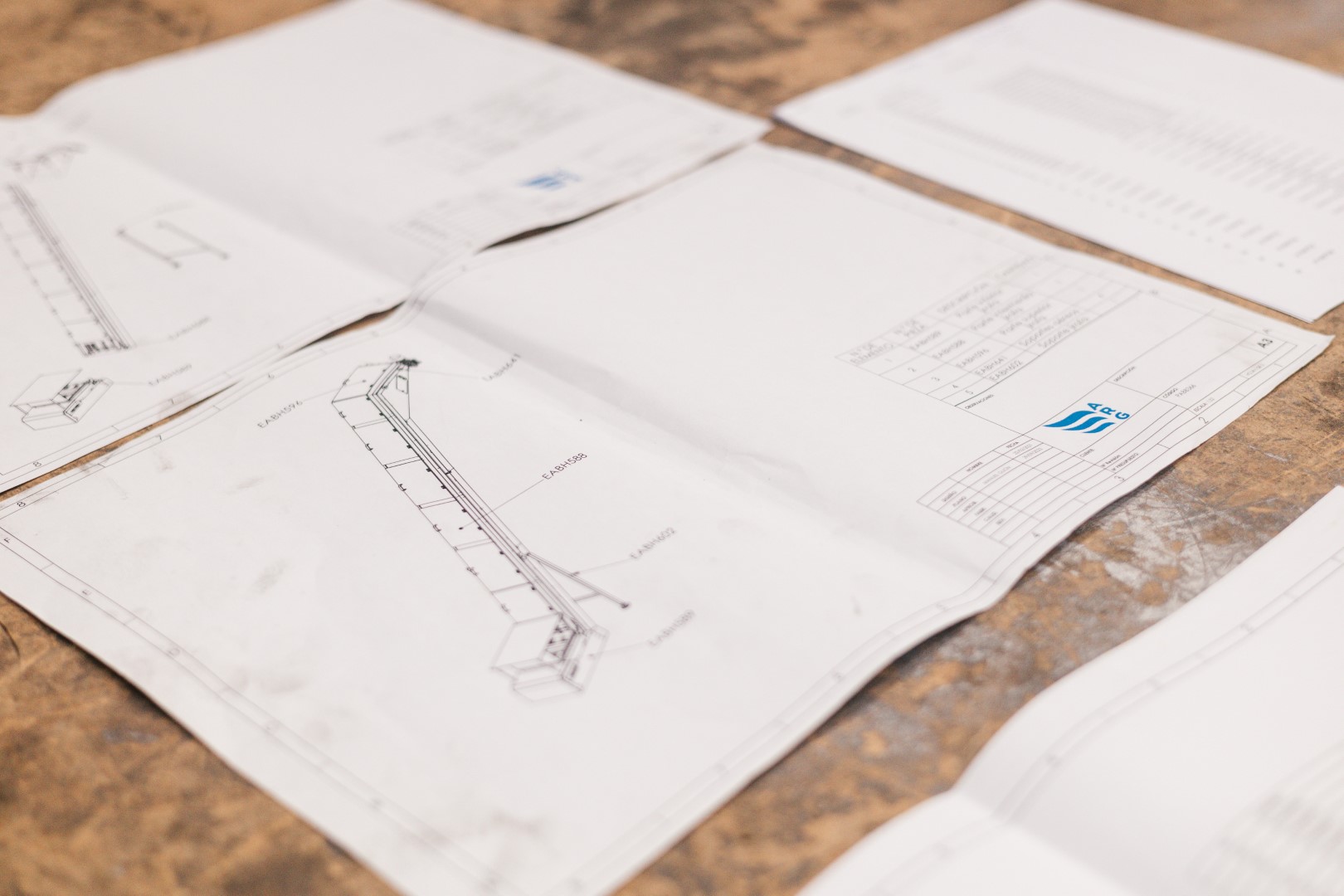

ARG BOTTLING Process Engineering, we are in charge of designing, optimizing, controlling and managing all the processes that are involved in the production rooms and filling lines, from the reception of raw materials to the final filling, in a sustainable, safe, and secure manner. quickly and at a low cost, ensuring that the client obtains maximum results.

Do you have a project?

Ask us your ideas and needs, we will make you a customized project, turnkey